Cable Assembly Potting & Encapsulation

Our Potting & Encapsulation Offer

Are you looking for a reliable and trustworthy partner to undertake your Potting and/or Encapsulation requirements? Well, you’ve come to the right place. For almost 20 years, WH Kemp has been the preferred port of call for some of the best-known engineering and electronic companies in the country.

Potting and Encapsulation were added to our growing portfolio of sub-assembly services in 2002. This followed repeated requests from our traditional Wiring Harness and Cable Assembly customers and coincided with the relocation to our 25,000 sq ft factory site – a move which in turn enabled the establishment of a purpose-built Potting and Encapsulation facility.

In addition to buying into our now inherent specialist Potting and Encapsulation experience – garnered over two decades – many customers have come to recognise that it can be significantly more cost efficient to outsource what is a difficult and grimy process requiring investment in specialist machinery and dedicated teams of individuals.

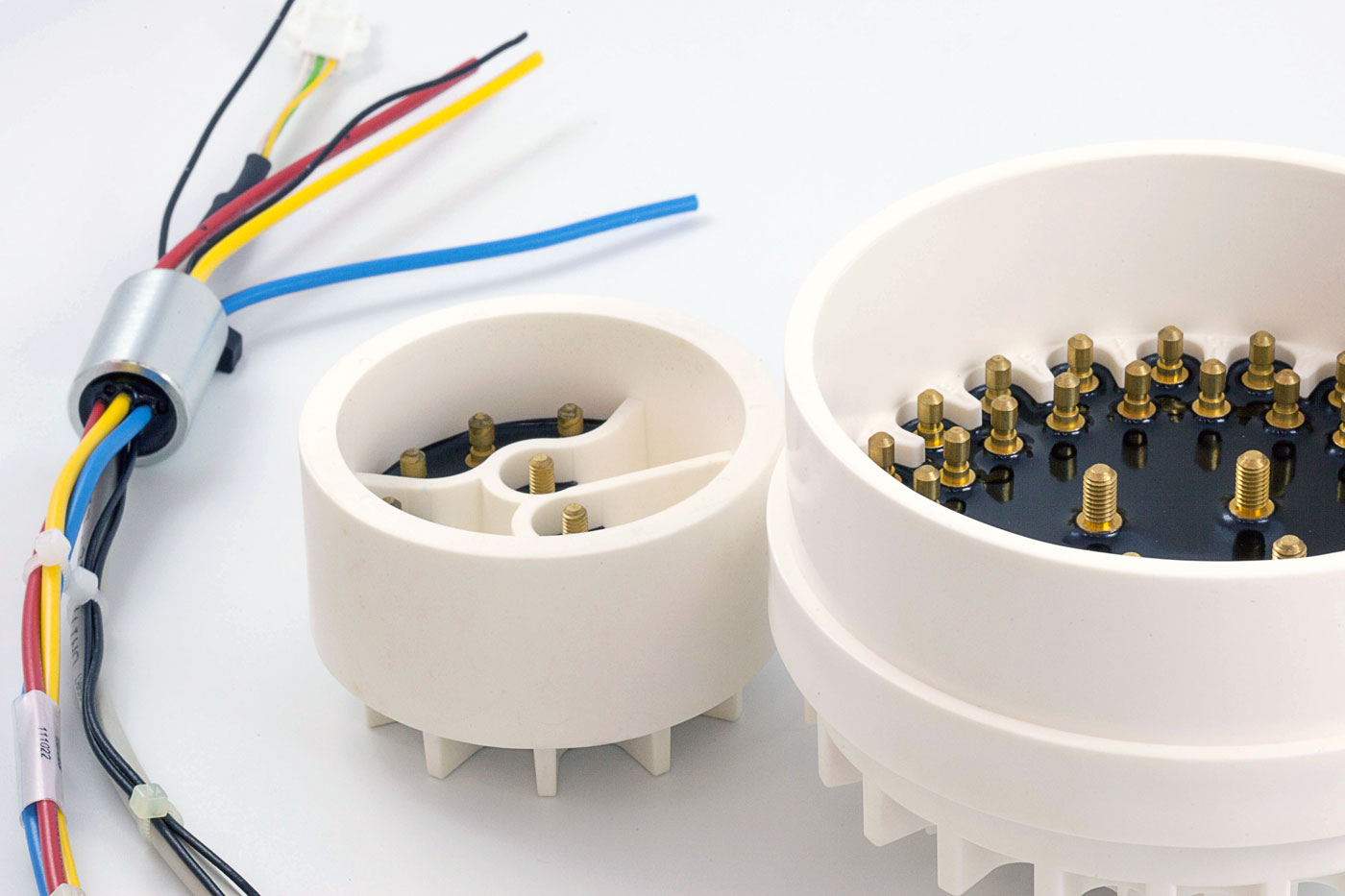

Potting and Encapsulating refers to a gelatinous compound or liquid resin, designed to envelop and protect electrical components.

The activity acts as a barrier to moisture/water penetration, as well as protecting electrical devices and components from dust build-up, corrosive elements, inadvertent physical tampering, vibration and electric shock, thereby ensuring greater component reliability and greater longevity of electrical units.

What is Potting & ENCAPSULATION?

The two processes are broadly similar (and sometimes used as interchangeable terms), because both involve the pouring of a liquid resin over electrical components.

However, there is one key difference between the two activities. For Potting, the compound resin is poured into the top of, quite literally, a pot, thereby covering the device/components encased inside. Whereas for Encapsulation, the device is immersed, in its entirety, into the compound resin, thereby applying a coating around the exterior of the whole unit – an Encapsulated Unit.

The practice of filling Pots with resin, which acts as a flame-path barrier between two parts of a machine – the electrical components and flammable chemicals – is now very much an established part of our offer. Today we have earned a reputation for always meeting our customers’ requirements for encapsulation of components, typically those within metal housings.

WH Kemp uses a variety of epoxy resins, silicones and cementitious products. Epoxy resins are commonly used for their excellent adhesion, and provide outstanding chemical and water resistance together with high electrical insulating properties.

Our Potting & Encapsulation Experience

Our customers tend to operate in sectors as diverse and demanding as Defence, Rail, Marine, Oil & Gas, Utilities, Nuclear, Product Testing, Scientific and Fire Protection.

Since WH Kemp’s inception in 1967, the company has worked with world-class businesses well-versed in producing machines and instruments for deployment around the globe in the most challenging environments and climates. Here at WH Kemp, our long association with these companies means we understand, arguably more than most, the importance of absolute reliability.

Just as our customers’ needs and challenges have increased and adapted to suit ever harsher environments, so has our proficiency and skills to provide them with nothing short of the best products. Which is why we continue to invest in, and upgrade, our Potting and Encapsulation capabilities to suit every global eventuality.

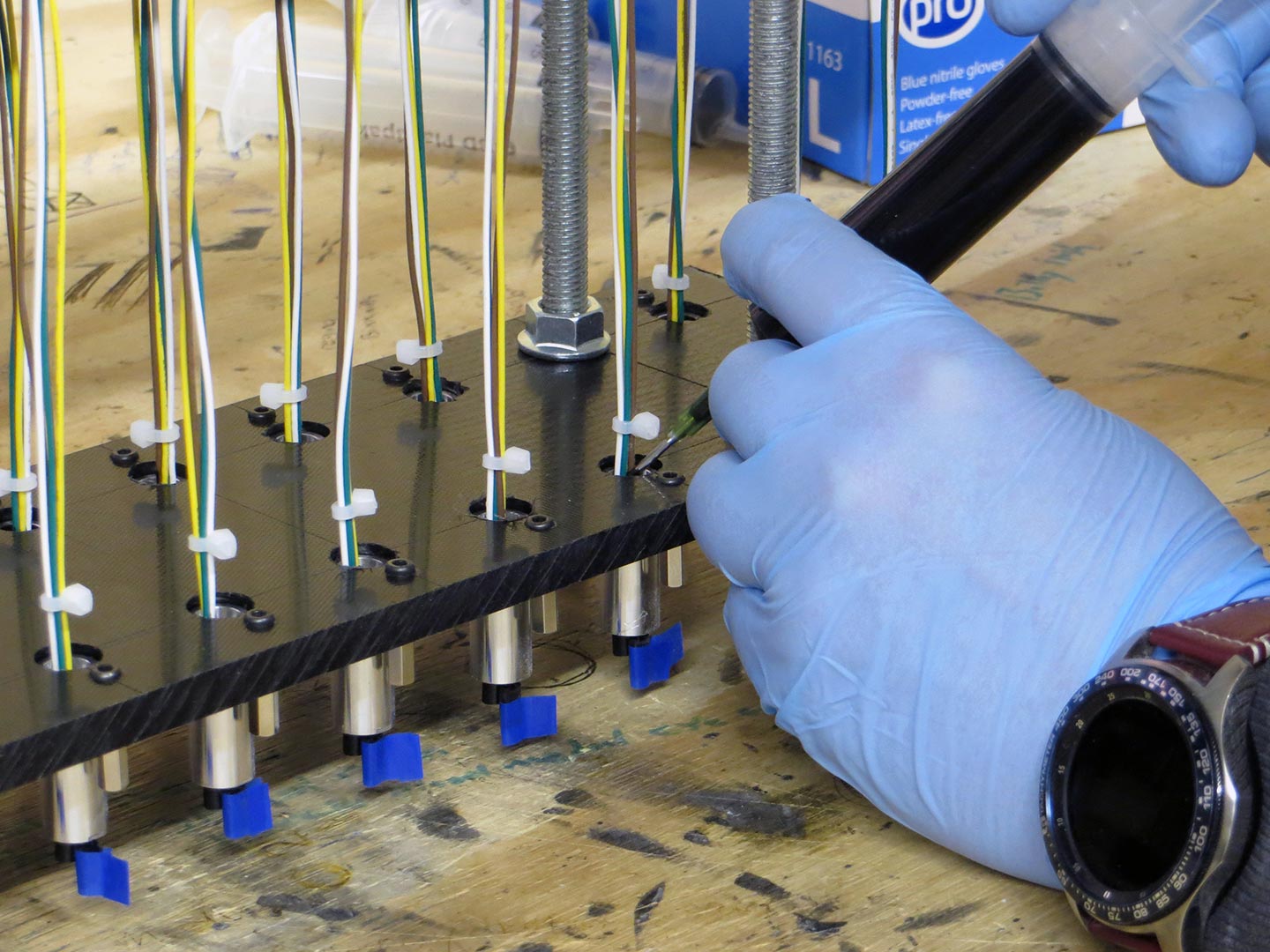

Our Process & People

Our 25,000 sq ft factory includes a dedicated, Potting and Encapsulation area, completely enclosed, in order to adhere to the necessary health and safety regulations. Full LEV (local exhaust ventilation) has been installed and elevated temperature curing is used to enhance product properties and process efficiency.

The Potting and Encapsulation facility is staffed by its very own team of experts, some of whom have been with us for over a decade, overseeing our potting and curing processes. Within our team we employ a qualified chemist with over 10 years of Potting experience. Armed with her BSc in Chemistry and her knowledge of quality tools and their practical application, Claire Borovac would be delighted to discuss potential/suitable products for your particular application.

We treat every customer’s assignment as unique, always ensuring Potting and Encapsulation timescales are met. For large-scale projects we can work closely with you the customer to set up a separate process area, thereby ensuring the most effective processes and finished product quality.

All products are subject to post-potting inspection and testing according to the individual customer’s requirement. This can involve pressure testing, electrical component function checks and leak tests.

Our Performance

All our products are manufactured within a Quality Management System conforming to ISO 9001:2015.

Samples of resin are taken for each batch and cured with the product, and then subjected to destructive testing and inspection. We are proud to say, as far as failure of potting compound is concerned, there have been zero customer rejects over the past 10 years.

Our technicians and team leaders are both approachable and responsive. And of course it goes without saying, WH Kemp’s quality and delivery on time performance is second to none!

Our Invitation

We actively encourage potential new customers to visit our Wiltshire base, easily accessible by road and rail. We would be delighted to take you on a tour of the site and introduce you to our friendly team who will gladly explain all aspects of our processes relating to our Potting and Encapsulation. Please call 01373 823322.

Our Services